In industrial composting facility—where they can break the bioplastic down into tiny pieces and compost it with very high heat, along with the proper mix of oxygen and a 2/3 mix of organic substrate.—it will biodegrade or compost over a short amount of time.

Industrial composting takes a few more weeks or months until it is ready to use because the microbial activity needs to balance, and the pile needs to cool. The waste is left in these vessels for seven days and temperature probes ensure that there is sufficient heat to kill any dangerous bacteria – it must achieve a temperature of 140°F for several consecutive days. The waste is then transferred to a maturation pad for the final stage of composting.

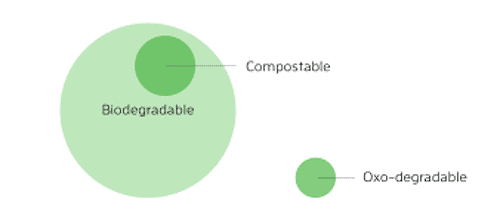

And keep in mind, NOTE ALL PLA is compostable, let alone biodegradable. Also, since PLA is an acid, it will raise the acidity of its surroundings as it composts. In the wild, it takes at least 80 years for PLA to decompose. To decompose, it needs specific conditions introduced: Oxygen, a Temperature of 140+ degrees, and a 2/3 Cocktail of an organic substrate.

Contamination is the biggest problem for municipal composting programs. Regular garbage is the most common contaminant. Nonbiodegradable items won’t necessarily harm the composting process, but separating the garbage from the compost can be messy and inefficient. And no one wants to buy compost that contains bits of plastic and other debris. Composting only works as a form of recycling if the resulting product is marketable.

Pura Vida Bioplastics = Real Certificates USDA BIO-BASED, TUV, BNQ, GREEN AMERICA Home Compostable – Breaks down 3-4 months without Chemicals

Get a Quote